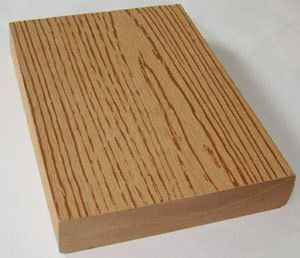

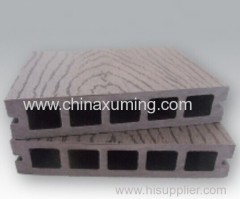

Wood Plastic Composite Outdoor Decking 90x25

Wood Plastic Composite outdoor flooring is a new type of environmentally friendly wood plastic

composite products, in production of high-density fiberboard produced by the process of lignans, adding

granulation equipment made of recycled plastic through WPC, then extrusion group made of wood flooring.

***Outline of WPC outdoor decking

WPC outdoor floor main material for PE and wood or bamboo powder, after adding additives, high speed

mixing, granulation, and then using an extruder extruded into pellets speaking profiles, such flooring

can be used in landscape, Villa other outdoor platform.

***Advantage of wood plastic composite outdoor decking:

1. Waterproof, moisture-roof . The fundamental solution to the damp wood products and more water

absorbent damp environment perishable ,Expansion deformation problem, you can use the traditional

wood products can not be applied to the environment .

2. Pest control , termite , effective way to eliminate insects harassment and prolong life.

3. Colorful , a wide selection of colors. Both natural wood color and wood grain texture , and can be

customized according to your own personality needs.

4. Plasticity, can be very simple personalized style, fully embodies the personal style .

5. High environmental protection, pollution-free, pollution-free, can be recycled. Product does

not contain substances , formaldehyde content of 0.2 , lower than the EO -class standards , environmental

standards for the European classification , can greatly reduce the amount of recycled wood to use for

national policy for sustainable development for the benefit of society.

6. A high fire resistance . Effective flame retardant, fire rating to B1 level , fire

self-extinguishing , does not produce any toxic gases.

7. Can be processed , and can be set , planing, sawing, drilling, surface can be painted .

8. installation, construction convenient, does not require complicated construction process , saving

installation time and costs.

9. No cracks, no swelling , no distortion , no repair and maintenance, easy to clean , repair and

maintenance cost savings late .

10. Sound-absorbing effect is good , good energy , indoor energy saving up to 30% .

***The information of wpc decking

Type | Engineered Flooring |

Place of Origin | Zhejiang, China (Mainland) |

Model Number | XM90S25-A |

| Size | 90x25mm;length depends as per customers' request |

Technics | Wood-Plastic Composite Flooring,extrusion |

Feature | Anti-UV, waterproof |

| Component | 35% HDPE+60% wood fibers + 5% additives |

Color | Different colors available |

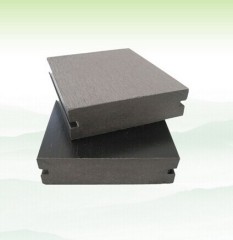

Decking section | Solid |

Surface Treatment | Wood grain |

| Quality Warranty | 15-25 years |

| Application | Swimming pool, garden, school, park, lawn,dock, playground, corridor, hotel , entertainment place, shopping center, laboratory ,living room , dance club , business hall, bathroom , massage room , etc . |

| Production Time | Within 30-45 days up receipt of your 30% deposit

|

| MOQ | At least one 20' container |

| Port of Loading | Ningbo or Shanghai |

| Payment Terms | T/T,L/C at sight |

| Sample Charge | Samples free, but you need to pay the freight |

***Performance of wood plastic composite outdoor flooring

1. The physical properties: strength, high hardness, non-slip, wear-resistant, no cracking, no insects,

small water absorption, anti-aging, corrosion resistance, anti-static and UV, insulation, thermal

insulation, fire retardant, resistant to 75 ℃ high and low temperatures of -40 ℃.

2. Environmental performance: Hazardous Substances ecological wood, green wood, renewable,

non-toxic substances, hazardous chemical ingredients, preservatives, formaldehyde, benzene and

other released, will not cause air pollution and environmental pollution can be 100% recycled

recycling and re-processing, can also be biodegradable.

3. The appearance of texture: a natural appearance of wood, texture. Better dimensional stability than

wood, no wood knots, will not crack, warp, deformation, products can be made from a variety of colors,

surfaces without secondary leaching paint new Nagakubo also does not fade.

4. Processing performance: secondary processing of wood has, as sawing, planing, bonding, with nails or

screws, various profiles of standards, construction and installation quick and easy. By conventional

practices, can be processed into a variety of facilities and products.