PPR Long Bypass Bend Pipe Fittings

***SPECIFICATIONS

|

Size

| Net Weight (g) | PCS/CTN | MOQ (cartons) |

| 20mm | 56g | 220 | 10 |

| 25mm | 67g | 130 | 10 |

| 32mm | 119g | 70 | 10 |

***Application Area:

1. Cold and hot water systems of residence and commercial buildings.

2. Transportation of industrial water supply and chemical materials.

3. Pure water pipe system.

4. Piping networks for rainwater utilization systems.

5. Irrigation systems for gardens.

6. Transportation system of drinking water production.

7. Piping networks for solar plants.

8. Other pipes in industry and agriculture.

***Characteristics of PP-R Pipes

1. Well heat resistance ability

The pipes can be used for a long time while the working temperature of water is 70°C. They can be used for a short time while it reaches 95°C. The softening temperature is 140°C.

2. Well insulation ability

The thermal conductivity of PP-R pipe materials is very low compared with steel and copper pipes.

Type of Materials | Thermal conductivity | Unit |

PP-R pipes | 0.21-0.24 | w/mk |

Steel pipes | 43-53 | w/mk |

Copper pipes | 333 | w/mk |

3. Long life span

Under normal conditions of temperature and pressure, PP-R pipes can be used for over 50 years.

4. Little resistance for water flow

The inner walls of PP-R pipes are smooth and limescale will not be formed there. The wear resistance factor is only 0.007, considerabally lower than the matel pipes. The ability for carrying water for PP-R pipes increases by over 30% than the metal pipes with the same size.

5. Environmental

During the process of production, construction and use, PP-R pipes will not make any pollution to the environment.

6. Economical

The price for PP-R pipes is almost the same with the galvanized pipes. With convenient construction, they are more cheap.

7. Light weight

The density of PP-R pipes is 0.89-0.9g/cm, only 1/8 of the steel pipes, 1/10 of copper pipes. The light weight will reduce the transportation cost and the construction intensity.

8. Healthy

The materials of PP-R pipes are formed with just two elements, that is, Carbon and Hydrogen. The sanitation performance of the materials has passed the examination by the government authority.

9. Well corrosion-resistance

Except for few oxidents, the pipes can endure the erosion of many kinds of chemical materials. The pipes will not be rusted, get eroded, breed the growth of bacteria.

10. Little expansion force

The flexible moludus of PP-R materials is small. So the expansion force formed with the change of temperature is little. They are suited for the installation of inside walls and concealed foor construction.

11. Complete accessories

PP-R pipe system have a full set of accessories and can meet the requirements of general project.

12. Solid connection

PP-R pipe system adopts the hot-welding way for connection. The pipes and fittings are linked together The tensile, bending and impact intensity at the interface is bigger than the pipe intensity, avoiding the hidden danger of water leakage.

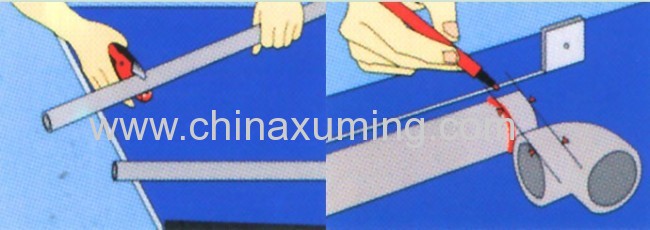

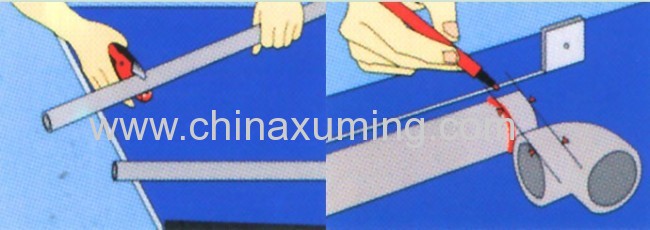

***WELDING STEPS OF PPE PIPES AND PPR PIPE FITTINGS:

***WELDING STEPS OF PPE PIPES AND PPR PIPE FITTINGS:

1.Cut pipe

When you disconnect the pipe, you must use the tube cutter vertical cut, because if there is no tube cutter, use other tools Xiaoduan pipe, after cutting off the head should be cleaned, insert the support sleeve.

2.Heating pipes and pipe fittings

When the tube is heated to fusion 260 ℃, while advancing the pipes and fittings in the welding device,

and heated to 5 seconds or more.

3.Connecting pipes and pipe fittings

The heated vertical pipe and pipe fittings to promote and maintain more than 5 seconds, do not overexert when advancing to

prevent the tube head bent.

(1).After construction is subject to acceptance pressure test before being sealed tube and use.

(2).Connecting water pipes and equipment should be installed in the device. Pump or fan coil and a receiver box must hose.

(3).When using a hot and cold water pipes, should take into account changes in thermal expansion and contraction.

(5).Insulation measures should not be direct contact between the pipe and the hanger. Hanger spacing shall meet the following

criteria:

(6).PP-R pipe hanger installation spacing

A:Cold water pipe hanger installation maximum spacing

| Nominal Diameter | 20mm

| 35mm | 32mm | 40mm | 50mm | 63mm | 75mm | 90mm | 110mm |

| Horizontal Pipe | 0.65

| 0.80 | 0.95 | 1.10 | 1.25 | 1.40 | 1.50 | 1.60 | 1.90 |

| Risers | 1.00

| 1.20 | 1.50 | 1.70 | 1.80 | 2.00 | 2.00 | 2.00 | 2.50 |

B:Hot water pipe hanger installation maximum spacing

| Nominal Diameter | 20mm

| 35mm | 32mm | 40mm | 50mm | 63mm | 75mm | 90mm | 110mm |

| Horizontal Pipe | 0.50

| 0.60 | 0.70 | 0.80 | 0.90 | 1.00 | 1.10 | 1.20 | 1.50 |

| Risers | 0.90 | 1.00 | 1.20 | 1.40 | 1.60 | 1.70 | 1.70 | 1.80 | 2.00 |

(6).As for the hot water pipes should increase the contact area between the bracket and the pipe.

(7).Installation location of various types of valves, import and export orientation must meet the design requirements, opening and

closing a flexible, easy to operate.

(8).Fill pipe should be installed on a one-way valve, the highest point of the system should be set to automatically release valve, inlet

and outlet connections shutoff valve must be installed.

(9).Import and export pumps near the tank should be installed thermometers, pressure gauges, filters and other components too

***OUR WORKSHOP AND PACKING